Occupational Health and Safety

Occupational Safety

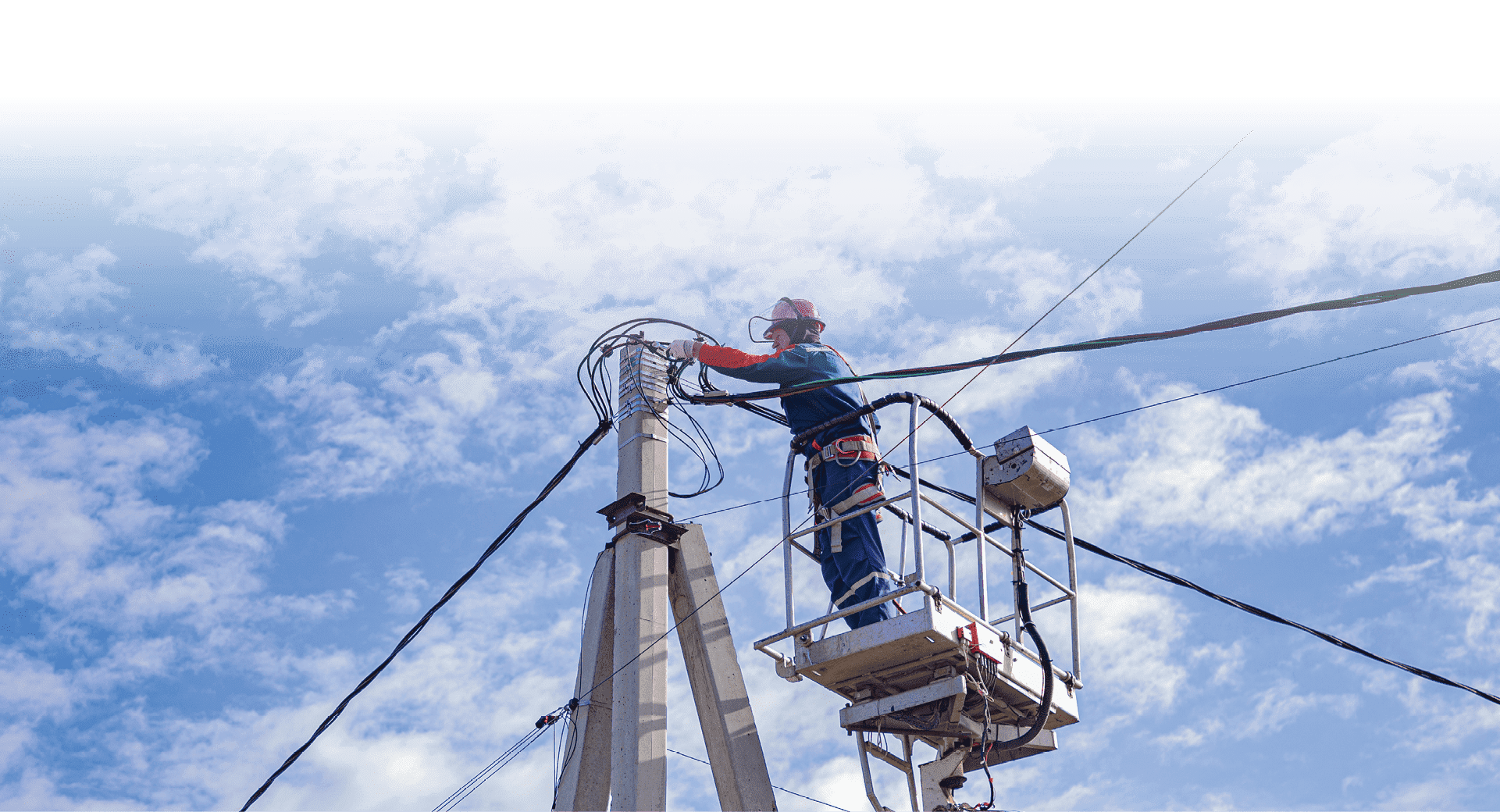

The key principle of the occupational safety activities of Rosseti Kuban is the recognition of and supporting the priority of employees’ lives and health as compared to the results of the Company industrial activities.

To establish a unified labour management system in the Company and to ensure safe and normal working conditions for employees at all stages of production, to monitor the compliance with occupational safety requirements at all levels of corporate management, the Company adopted STO 00104604-ISM 007-2018 Regulations on the Occupational Health and Safety Management System, which met the requirements of GOST 12.0.230-2007, interstate standards for occupational health and safety management systems, as well as the labour legislation of the Russian Federation.

The main occupational safety goals of Rosseti Kuban are as follows:

- Creation of a healthy and safe working environment

- Consistent and continuous reduction of work-related injuries and ill health

- High level of corporate safety culture

The occupational safety initiatives of the Company is aligned with the statutory requirements of the Russian Federation, regional laws, industry sector codes and rules, and executive documents.

The management of the Company is in charge of upholding secure working conditions and labour safety at Rosseti Kuban as well as their adherence to the established regulations. The Company fully complies with the requirements of the Russian laws regarding the occupational safety obligations of the employer.

The management of the Company (the Company’s branches) annually analyses and evaluates the achievement of the occupational safety goals. Following the functional analysis of the occupational health and safety management system in 2022, the Company considers the effectiveness of the total corporate efforts invested to be satisfactory.

During 2022, systematic work was carried out to improve occupational safety, prevent occupational accidents and improve working conditions:

- Occupational safety and health measures developed in accordance with the Tentative List of Annual Measures to Improve Working Conditions and Occupational Safety and to Eliminate or Reduce Occupational Risks or Prevent their Increase approved by Order No. 771n of the Ministry of Labour of the Russian Federation dated 29 October 2021

- Comprehensive programmes were implemented to reduce the risk of injuries to the Company’s personnel and third parties from electric shocks at the Company’s power grid facilities

- An annual study of the outcomes of the occupational safety work was conducted, goals for the following year were established, and a list was created to enhance working conditions and occupational safety, remove or decrease occupational risks, avoid injuries, and execute the Zero Injuries concept.

- Monthly video conference calls were held with the participation of directors, first deputy directors — chief engineers and heads of branch divisions

- Monthly occupational health and safety days were held, allowing many employees to be involved in the process of self-supervision and mutual supervision and increasing their knowledge and experience

- Business games were used to provide training on the functioning of the occupational health and safety system and the timely identification of potential hazards and risks to the health and lives of workers

- Timashevsk, Tikhoretsk and South-West Power Grids branches carried out comprehensive inspections of compliance with current legislation of the Russian Federation and local regulatory acts of the Company aimed at preventing occupational accidents and third-party injuries

- Heads of branches, business units and their deputies carried out unannounced inspections of workplaces to check the personnel’s compliance with occupational safety rules when organising and carrying out work in electrical installations

There were three work-related accidents during the reporting year, two more than in 2021. No work-related ill-health was identified among the Company’s personnel.

A unified helpline is operational in all divisions of the Company to receive automated voice and text messages (SMS) from staff regarding occupational safety concerns, details of rule violations, and recommendations for ways to enhance working conditions. This is done in an effort to eliminate the underlying causes of injuries and to reduce them. More than ten training films on the types of work performed were made, an anonymous questionnaire survey of personnel was conducted in order to identify the causes of violations of occupational safety rules and to collect proposals on improving and changing the current state of labour protection in the Company, Internet publications and articles on labour protection were placed on the official web pages of the branches, competitions on labour protection were held for the best structural subdivision and the best team car. A corporate newspaper, Safe Labour, was launched in 2022.

The Company’s personnel at risk for health reasons, in addition to periodic medical examinations, are referred for additional medical examinations under the voluntary health insurance scheme.

To promote employees’ health and life-span, the Company purchased necessary protection and safety equipment in 2022. Annual acquisition order for working wear and shoes was fully completed The unit cost of personal protective equipment per employee in 2022 was RUB 23,750, which is 4.8% higher than in 2021.

Following the Labour Code of the Russian Federation, the actions aimed at improving the working conditions and occupational safety at the Company are funded to at least 0.2% of the manufacturing costs for products (works, services); in fact, these activities were funded in the amount of 0.64% of the said amount.

Industrial Safety

The operational supervision for industrial safety is aligned with the Company’s order No. 550-od dated 28 September 2021 On the Appointment of Persons Responsible for Operational Supervision for Industrial Safety Requirement Implementation at Hazardous Facilities and with the Regulation of Operational Supervision for Industrial Safety Requirement Implementation at Hazardous Facilities approved by the Order No. 324 dated 9 June 2020 and elaborated in line with the following documents:

- Federal Law No. 116-FZ dated 21 July 1997 On Industrial Safety of Hazardous Production Facilities (as amended from time to time)

- Order No. 461 of the Federal Service for Environmental, Technological and Nuclear Supervision dated 26 November 2020 On Approval of Federal Standards and Rules for Industrial Safety of Hazardous Production Facilities, Safety Rules for Hazardous Production Facilities with Hoisting Equipment

- Decree of the Government of the Russian Federation No. 2168 dated 18 December 2020 On the Organisation and Implementation of Production Control over Compliance with Industrial Safety Requirements

The Company has three hazardous production facilities registered at the Federal Service for Environmental, Technological and Nuclear Supervision (certificate No. А30-00777 dated 13 October 2020). In 2022, the hazardous production facilities were operated following the requirements set out in technical reference documents.

The following measures were taken on the hazardous production facilities of Rosseti Kuban in 2022:

- 143 industrial safety reviews

- 191 partial technical inspections of equipment

- 69 full technical inspections of equipment

- 706 functional checks of safety devices

The following activities related to industrial safety training and attestation of employees were carried out in 2022:

- 266 employees received advanced training

- 648 employees were attested by the attestation commission on the Unified Testing Portal in the field of industrial safety, hydraulic structure safety, energy safety

- 102 employees were attested in the territorial attestation commission of the Federal Service for Environmental, Technological and Nuclear Supervision

Accounting and investigation of accidents, incidents at hazardous production facilities operated by the Company are performed in accordance with the approved procedure for technological investigation of causes of incidents at hazardous production facilities approved by Order of the Company No. 303-od dated 7 June 2021.